Electrical Conductors:

The most popular electrical conductors are Copper and Aluminum.

Copper is the popular choice for power distribution and control circuits because of its excellent ability to conduct electric current as well as other electrical and mechanical properties. Copper may be coated with Tin, Nickel or Silver to ensure easier soldering and to retard corrosion

Aluminium is also used in power applications. Its principal advantages are its weight and lower material cost when compared with copper.

The main disadvantages of Aluminium are :

(a) It has a lower conductivity than Copper hence it will require larger wire and cable sizes than Copper

(b) Aluminium oxidizes quickly when exposed to air. This oxidation acts as an insulator. This creates additional cost with regard to maintenance and testing when compared to Copper

Aluminium is widely used by the electric utilities in overhead lines primarily because of its light weight and cost when compared to copper.

Common Terms Used with Conductors:

(a) A wire is a single length of metal

(b) A stranded wire is a group of small wires that are braided or twisted together to produce a single conductor. The wires are not insulated from each other. A heavily insulated stranded wire is often called a cord. The outer jacket of a cord protects the wiring from physical damage.

(c) A cable can either be a solid, stranded conductor or a combination of conductors insulated from each other. This latter arrangement is called a multiconductor cable. In this cable, the wires may be stranded, may or may not have a common insulation covering

(d) A conductor carries electricity from generation equipment to utilization equipment. A conductor may be solid or stranded. A solid conductor is usually reserved for smaller wire sizes and provides the benefit of low weight and small diameter. A stranded conductor configuration is usually used for larger-sized wires as this configuration makes the cable lighter and more flexible.

(e) Insulators are non-conductors of electricity. However at a certain voltage known as the breakdown voltage, an insulator breaks down and becomes a conductor. Hence insulators are rated for a specific voltage which should not be exceeded.

(f) Insulation is the covering conductors are enclosed in. This insulation protects the wiring and prevents the electrical energy being carried from leaking into other materials to possibly cause damage and hazards

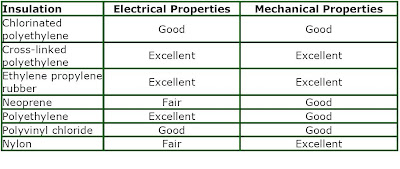

There are several insulating materials. The most commonly used are tabulated below along with their mechanical and electrical properties:

Series of letters are popularly used to identify cable insulation types. Some of the letters used are:

(i) MI – Mineral Insulation

(ii) R - Rubber Insulation

(iii) T - Thermoplastic Insulation

(iv) V - Varnished Insulation

(v) X - Cross-linked polymer Insulation

This lettering system is specified by NEC – National Electrical Code

The most popular amongst the above are thermoplastic and cross-linked polymer insulation

The ability of the insulation of the conductor material to withstand ambient conditions can be also be used to classify cable insulation for example:

H - Heat resistant up to 75 deg C

HH – Heat resistant up to 90 deg C

W - Moisture resistant

UF – For use in underground direct burial applications

There are popular cable types in use today that we should know of. Some of them are tabulated below:

In most industrial environment you are likely to see THHN/THWN and XHHW. They stand for:

CABLE DESIGNATION

THHN T - Thermoplastic insulation; HH - Heat resistant up to 90 degC ; N - Non-metallic

sheathed cable

THWN T - Thermoplastic insulation; H - Heat resistant up to 75 degC ; W - Moisture

resistant ; N - Non-metallic sheathed cable

XHHW X - Cross-linked polymer insulation ; HH - Heat resistant up to 90 degC

W - Moisture resistant